Instrumentation stands as a cornerstone in various industries, facilitating precise measurement, control, and monitoring of processes and equipment. From healthcare to aerospace, its significance is undeniable. In this article, we embark on a journey through the realm of instrumentation, addressing key questions to unveil its importance and diverse applications.

What defines instrumentation, and why is it indispensable?

Instrumentation encompasses the science and art of measuring and controlling variables within processes or systems. It comprises an array of devices, sensors, and instruments crafted to collect data, monitor conditions, and facilitate control mechanisms. Whether in industrial contexts, scientific endeavors, or everyday scenarios, instrumentation ensures accuracy, reliability, and safety. It empowers professionals to gather precise data, make informed decisions, and optimize performance. In sectors like manufacturing, healthcare, and environmental preservation, instrumentation serves as an indispensable tool for upholding quality standards, boosting productivity, and mitigating risks.

How does instrumentation fuel technological progress?

Instrumentation plays a pivotal role in driving innovations across various sectors. In fields like aerospace, automotive, and telecommunications, advanced sensors and instruments enable real-time monitoring, predictive maintenance, and automation. For instance, within the automotive industry, onboard instrumentation systems meticulously monitor engine metrics, emissions, and safety parameters, optimizing fuel efficiency and enhancing vehicle reliability. Similarly, within healthcare, medical instrumentation facilitates diagnostic imaging, patient monitoring, and drug delivery, thereby fostering improved treatment outcomes and patient care.

What are some prevalent types of instrumentation used across industries?

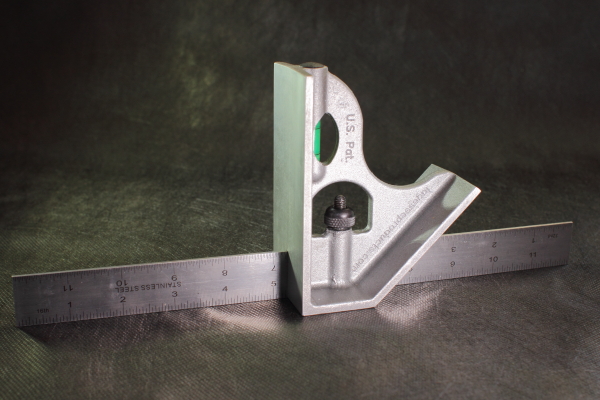

The sheer diversity of industries reliant on instrumentation underscores its adaptability and versatility across multifaceted applications. Common instrumentation types include pressure gauges, temperature sensors, flow meters, level sensors, and analytical instruments such as spectrometers and chromatographs.

In manufacturing, instrumentation serves as a linchpin for process regulation, quality assurance, and compliance with regulatory standards. Within environmental monitoring, instruments like air quality sensors and water quality analyzers contribute to tracking pollution levels and promoting environmental sustainability. Moreover, instrumentation plays a vital role in research fields like physics, chemistry, and biology, enabling scientists to conduct experiments, analyze data, and validate hypotheses.

How does instrumentation intersect with Geonet and its functionalities?

Geonet, harnessing instrumentation, collects, analyzes, and visualizes spatial data to monitor environmental parameters, track geological phenomena, and manage natural resources. It encompasses a wide range of sensors, GPS devices, and geographic information systems (GIS). In geology, instrumentation is crucial for studying seismic activity, monitoring volcanic eruptions, and assessing landslide risks. In agriculture, precision instrumentation aids in optimizing crop yields, managing soil fertility, and conserving water resources. Furthermore, in urban planning and disaster management, Geonet applications leverage instrumentation to assess infrastructure integrity, chart evacuation routes, and coordinate emergency responses.

Instrumentation serves as the backbone of modern technology, enabling precise measurement, vigilant monitoring, and efficient control across diverse industries. From enhancing productivity in manufacturing to ensuring safety in healthcare, instrumentation drives efficiency and innovation. By harnessing the power of instrumentation, businesses and researchers can unlock new opportunities, optimize processes, and tackle complex challenges. Whether it involves monitoring environmental dynamics or optimizing industrial operations, instrumentation remains indispensable in shaping a smarter, more sustainable future.