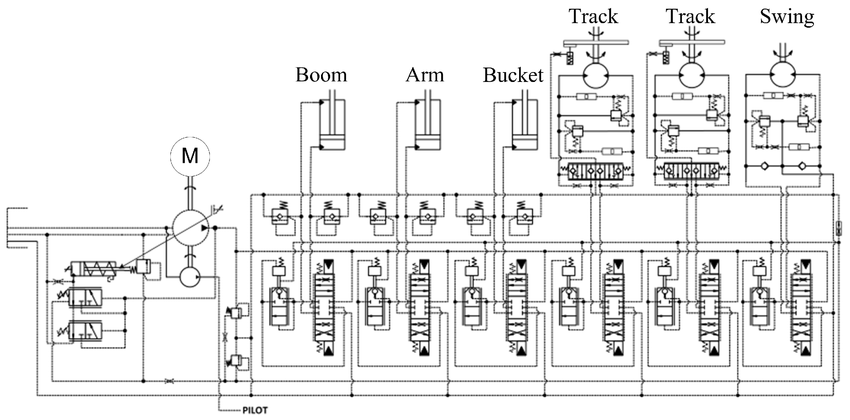

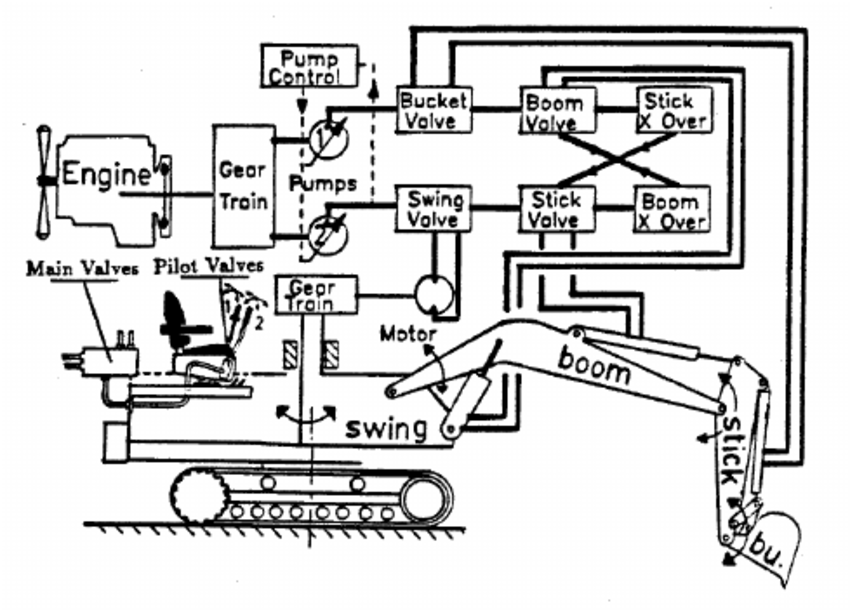

Hydraulic systems are at the heart of modern excavators, providing the power necessary for these machines to perform a wide range of tasks efficiently. By examining a diagram of an excavator’s hydraulic system, operators and enthusiasts can gain valuable insights into how these complex systems work. Here is a detailed explanation of a typical excavator hydraulic system based on a diagram:

Components of an Excavator Hydraulic System:

Hydraulic Pump:

The hydraulic pump is the heart of the excavator’s hydraulic system. It is typically powered by the engine and is responsible for generating the high-pressure hydraulic fluid required to operate the various hydraulic cylinders and motors on the machine.

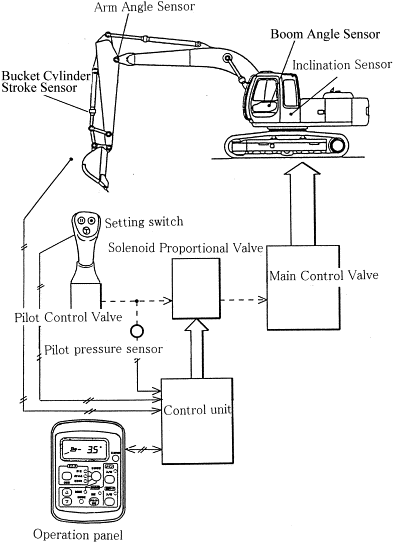

Control Valves:

Control valves are essential components that regulate the flow and direction of hydraulic fluid within the system. They control the actuation of hydraulic cylinders and motors, allowing operators to manipulate the boom, arm, bucket, and other attachments.

Hydraulic Cylinders:

Hydraulic cylinders are devices that convert hydraulic pressure into mechanical force. In an excavator, cylinders are used to control the movement of the boom, arm, and bucket, enabling precise positioning and operation of the machine.

Hydraulic Motors:

Hydraulic motors convert hydraulic pressure into rotational mechanical energy. In an excavator, hydraulic motors are commonly used to drive the machine’s tracks or wheels, allowing it to move across the job site.

Hydraulic Hoses and Fittings:

Hydraulic hoses and fittings are used to transport hydraulic fluid between the different components of the system. They must be properly sized, routed, and maintained to ensure efficient operation and prevent leaks.

Reservoir and Filters:

The hydraulic reservoir stores hydraulic fluid for the system, while filters help remove contaminants and maintain fluid cleanliness. Clean hydraulic fluid is essential for the proper functioning and longevity of the system components.

Cooling System:

Excavator hydraulic systems often include a cooling system to dissipate heat generated during operation. This helps prevent overheating and ensures the system operates within optimal temperature ranges.

Functioning of an Excavator Hydraulic System:

The hydraulic system of an excavator works by transmitting pressurized hydraulic fluid from the pump to the various components that need power. When an operator activates a control lever, the control valve directs the flow of hydraulic fluid to the corresponding cylinder or motor, causing the desired movement or actuation.

For example, when the operator moves the joystick to extend the boom, the control valve routes hydraulic fluid to the boom cylinder, causing it to extend and raise the boom. Similarly, manipulating other controls allows for precise control over the arm, bucket, swing, and other functions of the excavator.

Understanding the layout and operation of an excavator’s hydraulic system is crucial for operators to work efficiently and safely. Regular maintenance, inspection, and troubleshooting of the hydraulic system can help prevent breakdowns, ensure optimal performance, and extend the lifespan of the excavator.