In the world of fluid handling and transfer, the choice of pump plays a crucial role in ensuring efficiency and reliability. One notable type of pump is the Roper progressive cavity pump. This innovative pump design is particularly advantageous for transferring viscous fluids and slurries, making it a preferred choice in various industries, including oil and gas, wastewater treatment, and food processing. To fully appreciate the functionality of a Roper progressive cavity pump, it’s essential to understand its key components.

What is a Roper Progressive Cavity Pump?

A Roper progressive cavity pump is a type of positive displacement pump that utilizes a helical rotor and a stator to move fluids. The design allows for the smooth handling of thick, abrasive, or shear-sensitive materials. The pump’s unique mechanism ensures consistent flow rates, making it suitable for applications that require precision and reliability.

Key Parts of a Roper Progressive Cavity Pump

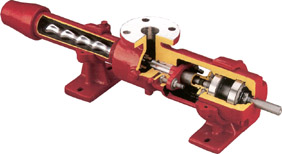

- Rotor

The rotor is a helical screw that rotates within the stator. It is typically made from hardened materials to withstand wear and tear. The rotor’s design allows for the efficient movement of fluid, creating pockets that help transfer the fluid smoothly and consistently through the pump. - Stator

The stator surrounds the rotor and is made from a flexible material, often rubber or elastomer. The stator’s inner surface is molded to match the rotor’s helically shaped design. As the rotor turns, the stator’s flexibility compensates for wear, maintaining a tight seal that prevents fluid leakage and ensures efficiency. - Drive Shaft

Connected to the rotor, the drive shaft transmits mechanical energy from the motor to the rotor to initiate its rotation. The shaft must be robust and properly aligned to minimize vibration and wear, ensuring the longevity of the pump. - Bearings

Bearings support the rotor and drive shaft, allowing for smooth rotation. They are crucial in maintaining the alignment of the pump components and reducing friction. High-quality bearings are essential for minimizing maintenance needs and enhancing pump performance. - Inlet and Outlet Ports

These ports facilitate fluid entry and exit from the pump. The design of these ports is critical to ensure a smooth flow and prevent air ingress, which can significantly impact performance. - Seals

Seals are used to prevent leakage at various junctions of the pump, including around the drive shaft and at the inlet/outlet connections. Efficient sealing is paramount in maintaining the pump’s operational integrity, especially when handling corrosive or viscous fluids. - Gearbox

In many cases, a gearbox is included to reduce the speed of the motor and increase the torque delivered to the rotor. This setup is essential for optimizing the pump’s efficiency, allowing it to handle thicker materials without deriving excessive power from the motor.

Advantages of Using Roper Progressive Cavity Pumps

The distinctive design of Roper progressive cavity pump parts allows for several advantages:

- Versatility: These pumps can handle a wide range of fluids, from thick slurries to shear-sensitive liquids, making them applicable in various industries.

- Consistent Flow Rates: The design allows for precise control of flow rates, essential for processes that require accurate dosing or mixing.

- Durability: With the use of high-strength materials in key components like the rotor and stator, Roper pumps exhibit excellent durability, even in harsh conditions.

- Low Maintenance: The design minimizes wear on moving parts, contributing to lower maintenance costs and longer operational life compared to other pump types.

Applications of Roper Progressive Cavity Pumps

Roper progressive cavity pumps are utilized across diverse applications:

- Oil and Gas: Ideal for transporting crude oil and other viscous fluids.

- Food Processing: Frequently used for pumping pastes, sauces, and other thick food products.

- Wastewater Treatment: Effective in moving sludge and other thick wastewater materials.

Conclusion

Understanding the Roper progressive cavity pump parts and their functions is crucial for anyone involved in fluid handling operations. The pump’s innovative design, combined with its robust components, allows for efficient and reliable fluid transfer in various applications. By selecting a Roper progressive cavity pump, industries can ensure optimal performance, reduced maintenance, and greater versatility in managing complex fluid dynamics.