Progressive cavity pumps have become increasingly essential in various industries due to their ability to handle challenging fluids with precision and efficiency. These pumps utilize a unique design that allows for consistent flow rates, making them ideal for applications where pressure and volume need careful control. One critical aspect of assessing the performance of a progressive cavity pump is the analysis of the progressive cavity pump curve.

The Basics of Progressive Cavity Pumps

Progressive cavity pumps, also known as eccentric screw pumps, consist of a helical rotor that rotates within a fixed stator. This design creates a series of sealed cavities that progressively transport fluid from the inlet to the outlet. The geometry of the rotor and stator is crucial; it determines the pump’s performance characteristics, including flow rate and pressure capabilities.

These pumps are particularly well-suited for handling viscous fluids, slurries, and shear-sensitive materials. Industries such as wastewater treatment, food and beverage, and oil and gas rely heavily on these pumps due to their robustness and versatility.

Importance of the Pump Curve

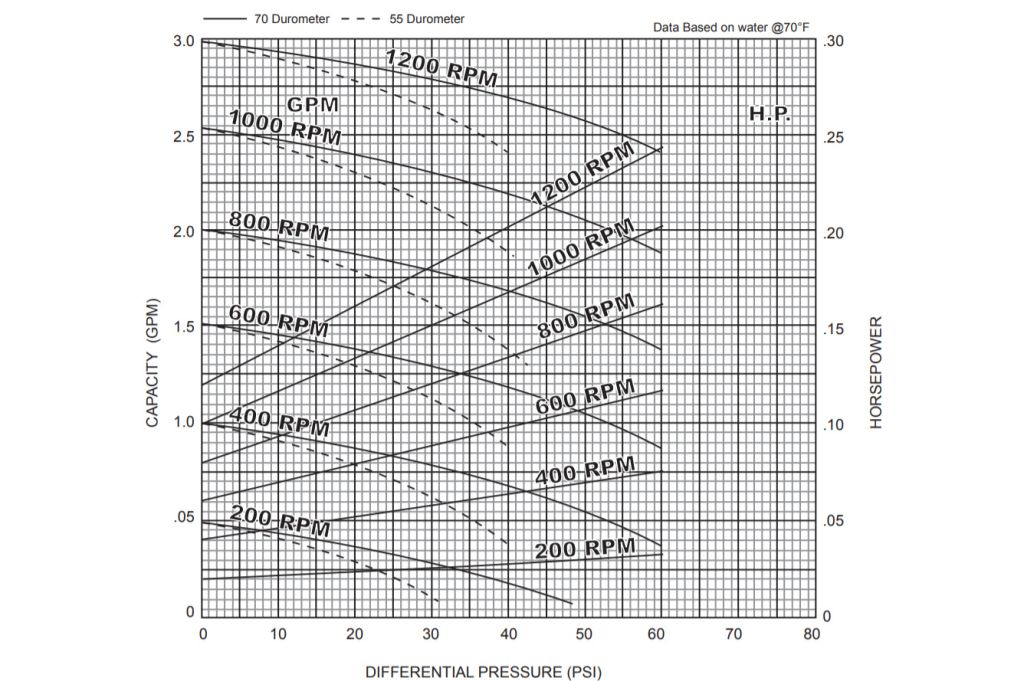

The progressive cavity pump curve is a graphical representation of the relationship between flow rate and pressure. Understanding this curve is vital for engineers and operators because it provides insights into the pump’s operating conditions and efficiency.

The pump curve typically features several key components:

- Flow Rate (Q): Represented on the horizontal axis, flow rate is measured in volume per unit time (e.g., liters per minute). It indicates how much fluid the pump can move at various conditions.

- Pressure (P): Shown on the vertical axis, this represents the pressure the pump can generate at different flow rates. It is usually measured in bars or pounds per square inch (psi).

- Efficiency Line: This line demonstrates how efficiently the pump operates across various flow rates and pressures. A higher efficiency indicates that the pump is converting more energy into fluid movement rather than losing it as heat or vibrations.

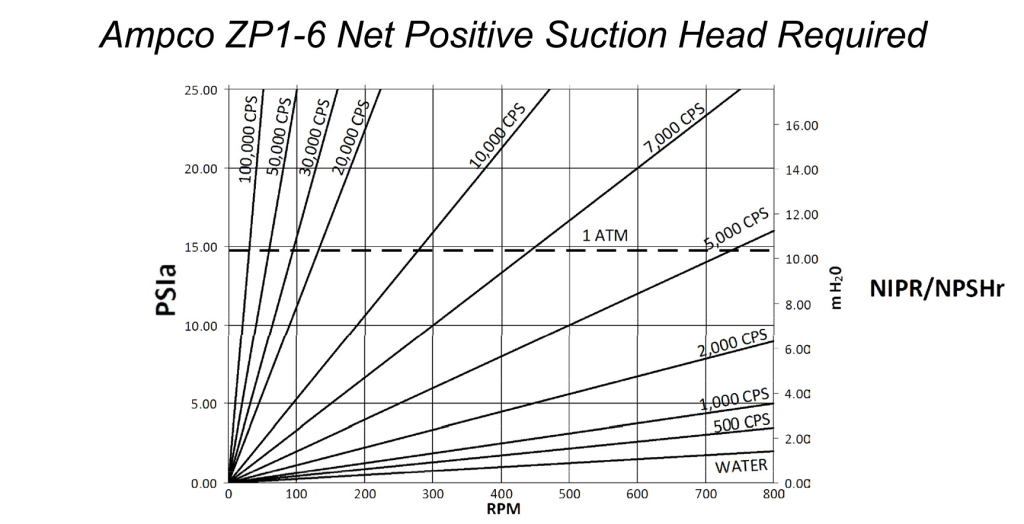

- Net Positive Suction Head Required (NPSHr): This portion of the curve indicates the minimum pressure needed at the pump’s inlet to prevent cavitation, which can damage the pump and decrease performance.

Analyzing the Pump Curve

By examining the progressive cavity pump curve, engineers can determine the best operating point for their applications. The intersection of the flow rate and pressure lines provides the optimal operating point, often referred to as the Best Efficiency Point (BEP). Operating at or near the BEP enhances the pump’s lifespan and minimizes maintenance costs.

Additionally, the pump curve can help identify conditions where the pump may experience cavitation. If the operational flow rate lies below the NPSHr line, the risk of cavitation increases significantly. Cavitation can lead to severe damage, reducing the lifespan of the pump and increasing operational costs due to frequent repairs.

Factors Influencing Pump Performance

Several factors influence the shape and characteristics of the progressive cavity pump curve:

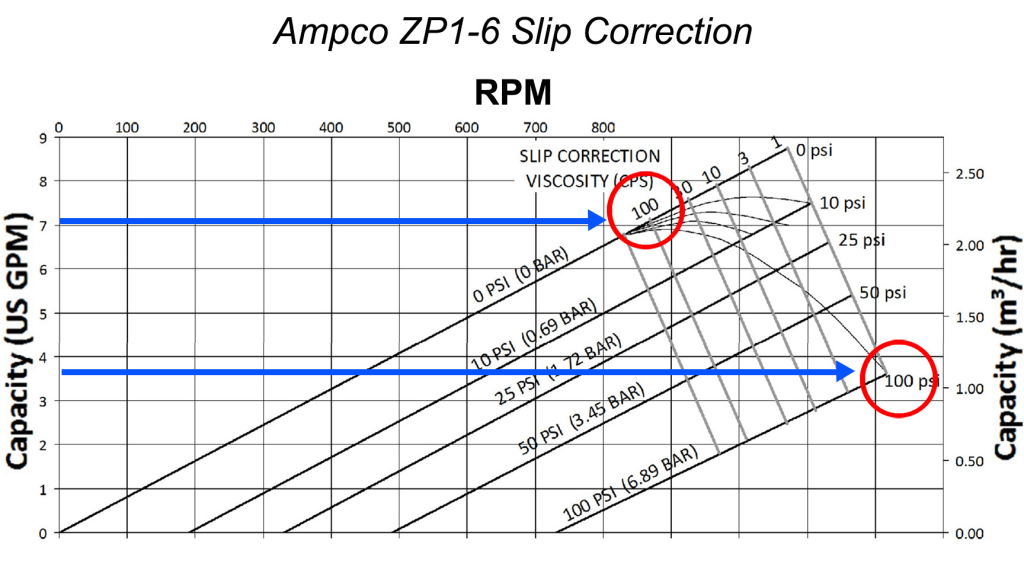

- Fluid Properties: The viscosity, density, and temperature of the fluid being pumped directly affect performance. Thicker fluids require more energy, which may be reflected in the pump curve.

- Rotor and Stator Design: Variations in geometry can lead to different flow behaviors, impacting the shape of the pump curve. Custom designs can optimize performance for specific applications.

- Speed: The rotational speed of the rotor also plays a crucial role. Higher speeds generally increase the flow rate but may decrease efficiency if the pump is not correctly matched to the application.

- Maintenance and Wear: As pumps age and wear occurs, the performance characteristics change. Regular monitoring and maintenance are essential to ensure the pump continues to operate within its efficiency range.

Conclusion

In summary, the progressive cavity pump is a critical tool in many industries, thanks to its ability to transport a wide variety of fluids efficiently. Understanding the progressive cavity pump curve provides essential insights into selecting the right pump for specific applications and helps ensure optimal performance and longevity. By carefully analyzing the pump curve and considering the factors that influence its shape, operators can make informed decisions that lead to improved efficiency, reduced maintenance costs, and enhanced reliability in their pumping systems.