Progressive cavity pumps are essential in industries such as oil and gas, mining, and water treatment. Proper maintenance and replacement of spare parts are crucial to ensure efficient and reliable operation. This comprehensive guide covers the key components, including the rotor, stator, universal joints, and seals, providing detailed information on their functions, common wear patterns, and replacement recommendations. By understanding the importance of genuine Roper pump progressive cavity spare parts, you can maximize your equipment’s performance, minimize downtime, and keep your operations running smoothly.

What is a Progressive Cavity Pump?

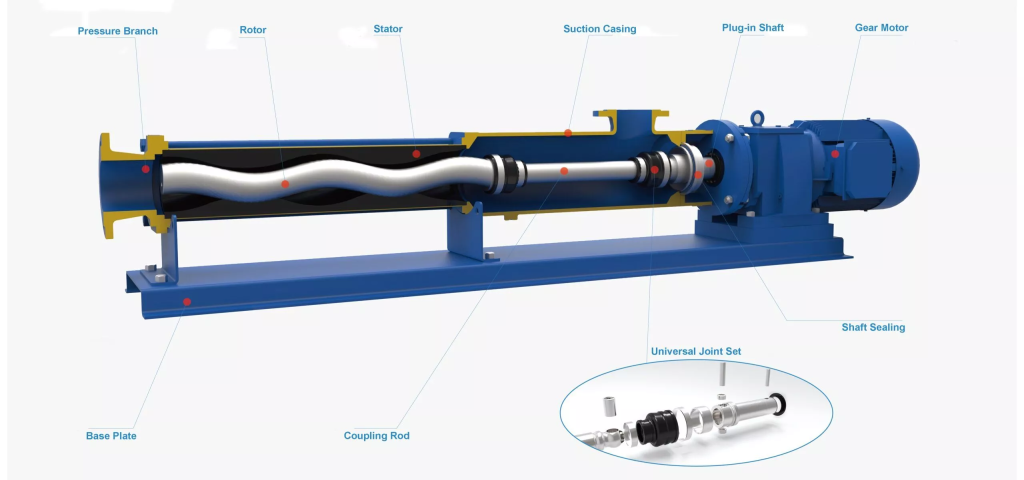

A progressive cavity pump consists of a helical rotor that rotates within a stator, creating a series of cavities that transport fluids. This unique design allows for a continuous, smooth flow, making it ideal for applications such as:

- Wastewater Treatment

- Food and Beverage Processing

- Oil and Gas Extraction

- Chemical Manufacturing

Key Components of Progressive Cavity Pumps

Understanding the main components of progressive cavity pumps is essential for effective maintenance and replacement of spare parts.

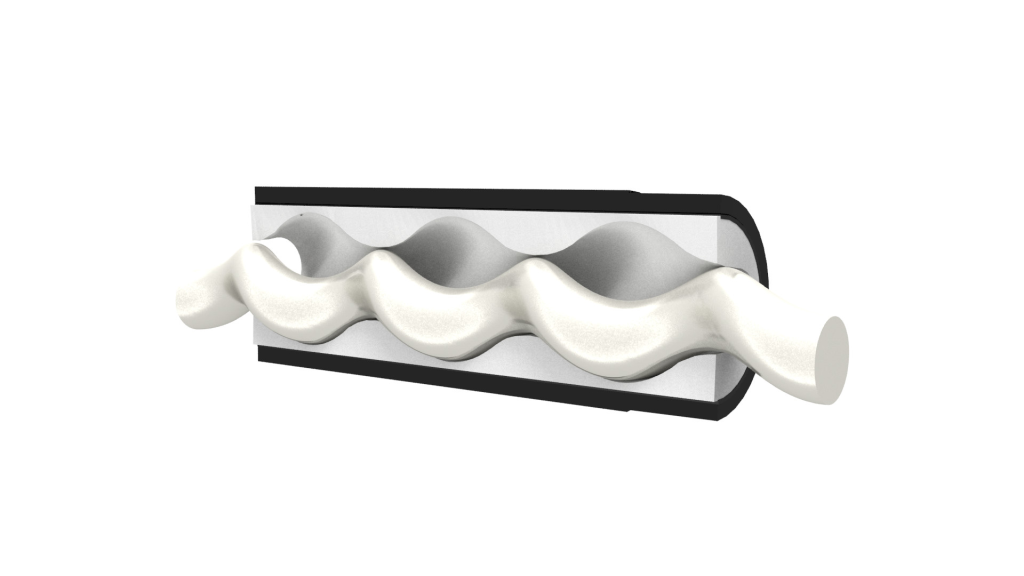

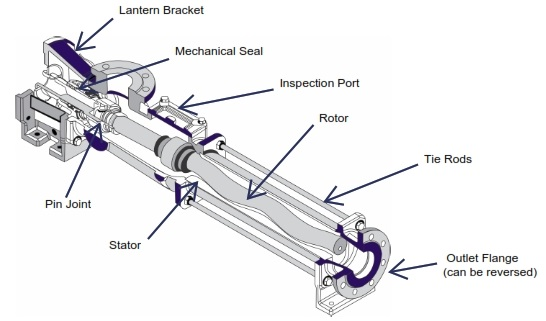

1. Rotor

- Description: The rotor is a helical-shaped component that rotates within the stator.

- Importance: It creates the pumping action by moving fluid through the cavities.

- Wear Indicators: Look for signs of wear, such as scoring or uneven surfaces.

2. Stator

- Description: The stator is a fixed component made of elastomer that contains the rotor.

- Importance: It provides the necessary sealing and helps maintain the pressure of the fluid.

- Wear Indicators: Inspect for abrasions or loss of elasticity.

3. Seals

- Description: Seals prevent fluid leaks and contamination.

- Importance: They maintain the integrity of the pumping system.

- Wear Indicators: Check for cracks or deformation.

4. Bearings

- Description: Bearings support the rotor and allow for smooth rotation.

- Importance: They reduce friction and wear on the rotor.

- Wear Indicators: Listen for unusual noises or check for excessive play.

Choosing the Right Spare Parts

1. OEM vs. Aftermarket

- OEM Parts: Original Equipment Manufacturer parts are recommended for their compatibility and reliability.

- Aftermarket Parts: While often cheaper, these may not offer the same quality and performance.

2. Material Considerations

- Select spare parts made from durable materials that can withstand the specific fluid characteristics, such as temperature and viscosity.

Best Practices for Maintenance

1. Regular Inspections

- Schedule routine inspections to identify wear and tear on components. This can prevent unexpected failures.

2. Monitoring Performance

- Keep track of flow rates, pressure, and power consumption to detect any anomalies that may indicate spare part issues.

3. Staff Training

- Train staff on proper pump operation and maintenance practices to enhance the overall efficiency of the system.

Replacement Guidelines

1. Timely Replacement

- Replace worn or damaged parts promptly to avoid further damage to the pump.

2. Proper Installation

- Ensure that all spare parts are installed correctly to maintain the integrity of the pump and avoid leaks.

3. Documentation

- Keep records of all maintenance activities and parts replacements for future reference and analysis.

Conclusion

Understanding and maintaining the spare parts of progressive cavity pumps is vital for ensuring optimal performance and longevity. By following this comprehensive guide, operators can effectively manage their pump systems, minimizing downtime and maximizing productivity. Investing in quality spare parts, regular maintenance, and staff training will ultimately lead to a more efficient and reliable pumping operation. Remember, in the world of progressive cavity pumps, a proactive approach is key to “Pumping Up Progress.”