Progressive cavity pumps are essential components in various industries, known for their ability to handle viscous fluids and provide a consistent flow rate. This article examines the landscape of progressive cavity pump manufacturers, highlighting their significance, challenges, and innovations in the field.

Understanding Progressive Cavity Pumps

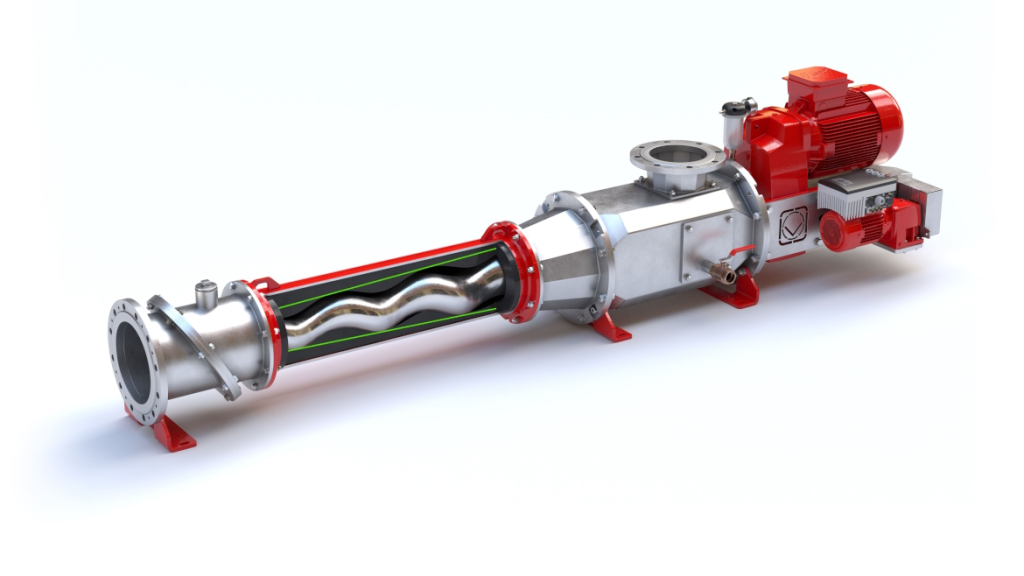

Progressive cavity pumps operate on a unique principle. They use a helical screw within a stator to create cavities that progressively move fluid from the inlet to the outlet. This design allows them to handle a wide range of fluids, including slurries, chemicals, and even food products. Their ability to maintain a steady flow makes them invaluable in applications where precision is critical.

Key Features of Progressive Cavity Pumps

- Consistent Flow Rate: Unlike some other pump types, progressive cavity pumps provide a smooth and continuous flow.

- Handling Viscous Liquids: They excel at pumping thick, viscous fluids that are challenging for standard pumps.

- Self-Priming: Many models can self-prime, reducing installation complexity.

- Versatility: Suitable for various industries, including wastewater treatment, pharmaceuticals, and food processing.

The Landscape of Manufacturers

The market for progressive cavity pumps is populated by numerous manufacturers, each offering unique products and services. Understanding the key players can help businesses make informed decisions.

Major Manufacturers

- Manufacturer A

Known for its innovative designs and high-quality materials, Manufacturer A focuses on energy efficiency and durability. Their pumps are widely used in the food and beverage industry. - Manufacturer B

This manufacturer specializes in custom solutions, catering to niche markets. They offer a range of sizes and configurations, making them a go-to for specialized applications. - Manufacturer C

With a strong emphasis on technology, Manufacturer C integrates smart monitoring systems into their pumps. This feature allows for real-time tracking and predictive maintenance. - Manufacturer D

Renowned for their robust construction, Manufacturer D’s pumps are ideal for harsh environments. They are commonly used in mining and heavy industrial applications. - Manufacturer E

This manufacturer is recognized for its commitment to sustainability. They produce pumps designed to minimize energy consumption and reduce waste.

Challenges in the Industry

While the demand for progressive cavity pumps continues to grow, manufacturers face several challenges that can impact their operations and product offerings.

Common Challenges

- Material Selection: Choosing the right materials for different applications is crucial. Manufacturers must ensure their pumps can withstand various chemical compositions and temperatures.

- Market Competition: The increasing number of manufacturers leads to intense competition, pushing companies to innovate and reduce costs without sacrificing quality.

- Technological Advancements: Keeping up with rapid technological changes requires significant investment in research and development. Manufacturers must adapt to new trends, such as automation and IoT integration.

- Regulatory Compliance: Compliance with industry standards and regulations can be complex and requires ongoing attention and resources.

Innovations in Progressive Cavity Pumps

To stay competitive, manufacturers are continually innovating their product lines. Some notable trends include:

Recent Innovations

- Smart Technology: Many manufacturers are integrating IoT and smart technology into their pumps, allowing for remote monitoring and predictive maintenance.

- Improved Sealing Solutions: Advances in sealing technology have led to better reliability and reduced maintenance needs.

- Energy Efficiency: New designs focus on reducing energy consumption, making pumps more sustainable and cost-effective.

- Modular Designs: Manufacturers are increasingly offering modular designs that allow for easy upgrades and custom configurations.

Conclusion

The world of progressive cavity pump manufacturers is dynamic and continually evolving. With the ability to handle a wide range of applications and the increasing focus on innovation and sustainability, these manufacturers play a crucial role in various industries. By understanding the key players, challenges, and innovations, businesses can make informed decisions that align with their operational needs. As technology progresses, the future of progressive cavity pumps looks promising, paving the way for enhanced efficiency and reliability.