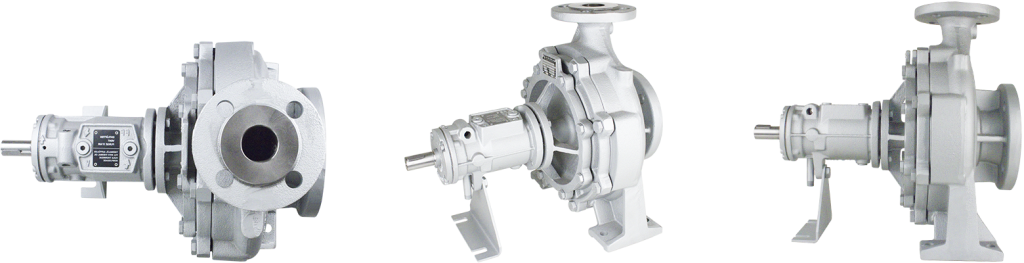

In various industrial sectors, the efficiency of fluid handling systems relies heavily on the quality of the pumps used. Allweiler, a well-known manufacturer of progressive cavity and centrifugal pumps, provides robust solutions for a variety of applications, including chemical processing, marine, and food production. Understanding the importance of Allweiler pump parts is crucial for ensuring the optimal performance and longevity of these pumps.

Key Components of Allweiler Pumps

Allweiler pumps are composed of several critical parts, including impellers, casings, and seals. Each of these components plays a vital role in the pump’s operation. For instance, the impeller is responsible for converting mechanical energy into kinetic energy, thereby moving fluids efficiently. On the other hand, seals prevent leaks, which is essential in maintaining safety and operational reliability.

Maintenance and Replacement of Pump Parts

As with any mechanical system, regular maintenance of Allweiler pump parts is essential. Over time, these parts can experience wear and tear due to constant use, leading to decreased efficiency and potential system failures. Regular inspections and timely replacements of worn parts can prevent costly downtimes and extend the life of the pump.

Using genuine Allweiler pump parts for replacements is crucial for maintaining compatibility and performance. Non-original parts might not meet the same quality standards, which can compromise the pump’s efficiency and lead to failure.

Improving Efficiency and Reliability

Investing in quality Allweiler pump parts not only enhances pump reliability but also improves overall system efficiency. Well-maintained pumps function at optimal capacity, consuming less energy and reducing operational costs. This is particularly important in industries where fluid handling is critical to production processes.

Conclusion

In conclusion, understanding the role of Allweiler pump parts is essential for any organization that relies on these systems. By prioritizing maintenance and using genuine replacement parts, companies can ensure the reliability and efficiency of their pumps. As industries continue to grow and evolve, maintaining robust fluid handling systems through quality parts will be key to operational success and sustainability.