Progressive cavity pumps are widely recognized for their efficiency in transferring fluids, particularly in challenging applications such as wastewater treatment, food processing, and chemical industries. The effectiveness of these pumps largely depends on their core components, which work in harmony to ensure optimal performance.

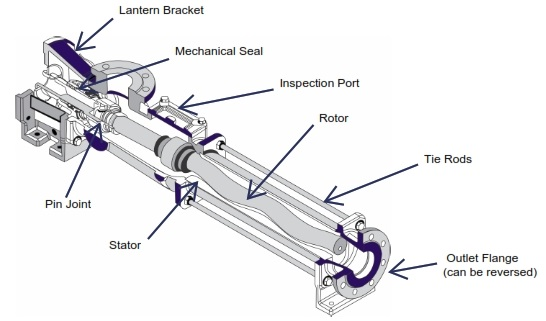

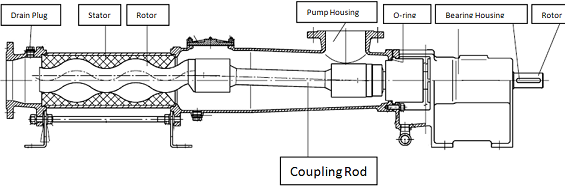

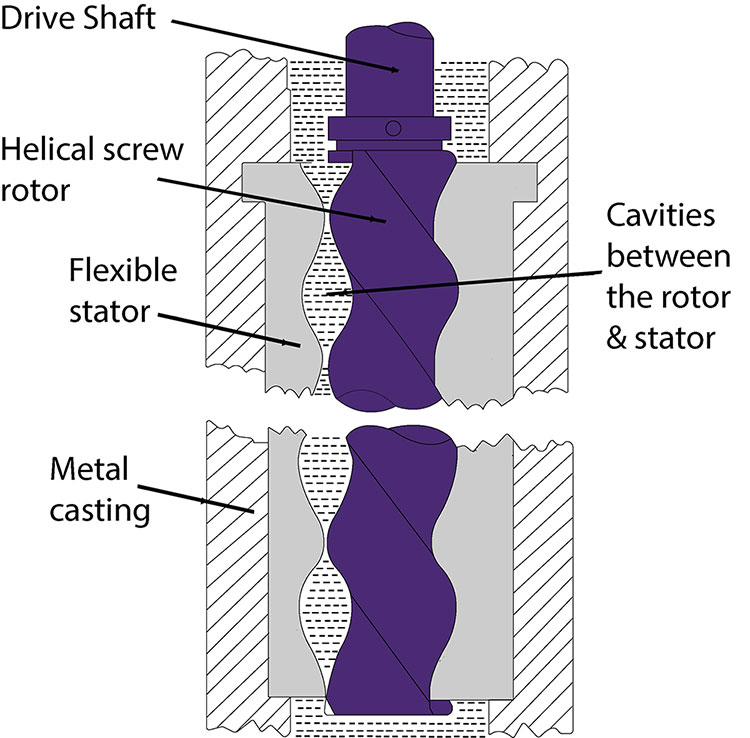

At the heart of a progressive cavity pump is the progressive cavity pump components, primarily consisting of a rotor and a stator. The rotor is a spiral-shaped screw that rotates within the stator, which is a helical-shaped cavity. As the rotor turns, it creates a series of sealed chambers that transport the fluid from the inlet to the outlet. This positive displacement mechanism allows for a smooth and continuous flow, making it ideal for handling viscous or shear-sensitive fluids.

Another critical component is the drive assembly, which powers the rotor. This assembly can vary in design, including electric motors or hydraulic systems, and it plays a crucial role in determining the pump’s efficiency. Additionally, the pump features various seals and bearings that protect against leaks and reduce friction, contributing to the overall reliability of the system.

Regular maintenance and timely replacement of these components are essential for ensuring the longevity and performance of progressive cavity pumps. Worn-out rotors and stators can lead to decreased efficiency and increased wear on other parts of the pump. Therefore, operators should monitor the condition of these components regularly.

In conclusion, understanding the progressive cavity pump components is vital for anyone involved in fluid management applications. By paying attention to the rotor, stator, and associated elements, operators can maximize the performance and reliability of their pumps, ultimately leading to increased productivity and cost savings. Proper maintenance and timely component replacement are key to achieving these goals.