key words:progressive cavity pump sizing,sizing progressive cavity pump

Downhole PC pump selection and sizing

Jump to navigationJump to search

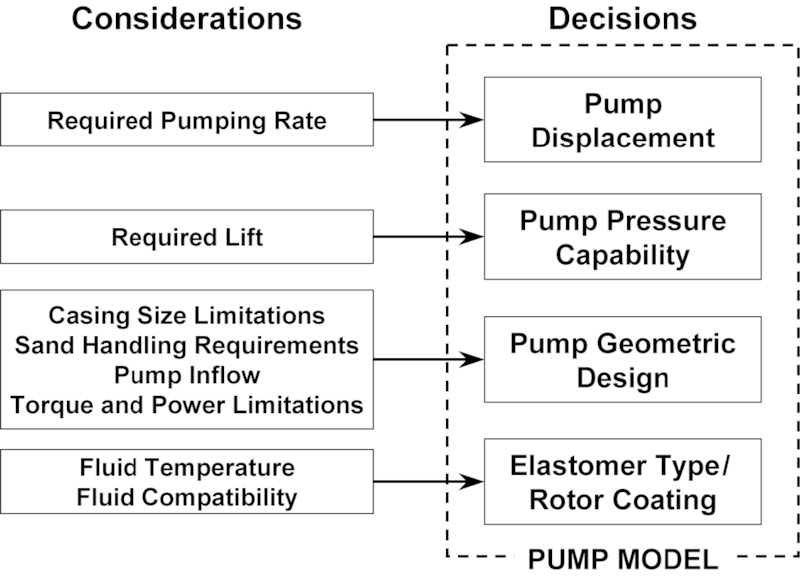

The key technical considerations and decisions involved in selecting a progressing cavity pump(PCP) for a particular application include pump displacement, pressure capability, geometric design, elastomer type, and rotor coating characteristics. Other factors, such as local vendor choice and economics can also affect pump selection. Fig. 1 provides a flow chart of the key decisions.

Pump Sizing is the process of dimensional matching an impeller and stator to provide a satisfactory performance test result and good service life during the operation of progressive cavity pumps. In this process, historical data analysis and dimensional monitoring are done manually, consuming a large amount of man-hours and requiring a deep knowledge of progressive cavity pump behavior. This work presents the use of complex networks in the construction of a prototype to recommend interference during the Pump Sizing process in a Progressive Cavity Pump. For this, data from different expert applications were used in addition to individual control Excel spreadsheets to build the database used in the prototype. From the pre-processed data, complex network techniques and the Betweenness Centrality metric were used to calculate the degree of importance of each order confirmation, as well as to calculate the dimensionality of the rotors. The model was evaluated using the mean squared error (MSE), obtaining a MSE of 0.28 for the cases where there were recommendations for order confirmations. Based on the results obtained, it was realized that there is a similarity with the dimensional defined by design engineers during the Pump Sizing process.